Address

South Section of Fenghuang 3rd Road, Gaoxin 19 Road, High tech Development Zone, Baoji City, Shaanxi Province

Tool Introduction:

Cement retainers are mainly used for temporary, permanent sealing or secondary cementing of oil, gas, and water layers. Through the retainers, cement slurry is squeezed into the wellbore section that needs to be sealed in the annulus or into the cracks and pores of the formation to achieve the purpose of sealing and plugging.

Structural features:

① The cement retainer is made of brass, rubber, and cast iron materials, all of which are easy to drill and grind;

② Cement retainers need to be used in conjunction with mechanical sealing tools. Before going down the well, it is necessary to connect the center pipe of the cement retainer to the control elastic joint of the mechanical setting tool, which cannot be tightened too much, and fix it with a shear pin;

③ Replacing the valve body on the retainer and one joint at the lower end of the seat sealing tool can achieve interchangeability with the bridge plug.

Operation:

① After lowering the tool string to the designated seating position, lift the pipe column up;

② Turn the column to the right and rotate the sealing tool at least 10 turns to the right. Unscrew the control nut from the thread on the center pipe and release the control sleeve at the same time;

③ Lower the pipe to the predetermined sealing position again. The friction between the arc-shaped spring and the casing can keep the control sleeve and the slip sleeve stationary. The lowering action can push the upper slip out of the slip sleeve. At this time, the spring plate on the upper slip sleeve can make the upper slip tightly adhere to the casing wall;

④ During the process of releasing the upper clamp, the support sleeve disengages from the cam block, and the cam block is ejected, thereby controlling the elastic joint to be released from the insertion joint, allowing for a certain relative axial movement between them;

⑤ Slowly lift the pipe column to apply the corresponding tension to the sealing tool, maintain the hanging weight for 5 minutes, and then lower it to the original hanging weight Slowly lift and stabilize for another 5 minutes (this process allows the rubber cylinder to fully expand, the upper and lower clamps to completely bite on the casing, and the tool has been seated), until the predetermined seating force is reached;

⑥ Apply a tensile force of 1t to the sealing tool, rotate the mechanical sealing tool to the right for more than 14 turns, cut off the shear pin on the bridge plug, and rotate the control elastic joint out of the bridge plug, then lift it up until it is released.

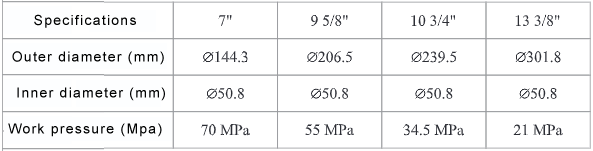

Technical parameters:

Address

South Section of Fenghuang 3rd Road, Gaoxin 19 Road, High tech Development Zone, Baoji City, Shaanxi Province

admin@bfdoil-tools.com

Phone

0917-6733216

13909178362

|

The company always adheres to

Guided by customer needs, we strictly control product quality, respond quickly to customer demands, efficiently provide products and solutions, and create tangible value for customers.

|

Mobile version QR code

|