Address

South Section of Fenghuang 3rd Road, Gaoxin 19 Road, High tech Development Zone, Baoji City, Shaanxi Province

Tool Introduction

The one-way oil pipe pressure test valve is a full bore tool used to perform multiple pressure tests on the working pipe string as required before squeezing cement or operation. When the leakage point is near the ground, the operator can locate the oil pipe leakage point. It can be used in conjunction with any Halliburton packer.

Structural characteristics

① The one-way oil pipe pressure test valve is operated by reciprocating motion and annular pressure or excess annular pressure on the oil pipe;

② When running in the well, use screws to position the ball valve in the open or closed position. After the screw is sheared, reciprocating motion will operate the ball valve;

③ The ball valve can be locked in the open position before exiting the well. Ring pressure is applied to cut the shear pin, and the shear pin body slides upwards, causing the lock block to sink into the groove of the spline lock sleeve; Once the locking block is stuck in the groove, the ball valve will be locked open, and when the pipe string is pulled out of the well, the liquid inside the pipe string will be discharged.

Operation method

Close the ball valve

Raise the work column. This function keeps the single stroke oil pipe pressure test valve in a stretched state and the ball valve will be closed; Pressurize the working column to test the pressure of the oil pipe.

Open the ball valve

Open the ball valve and lower the weight of the pipe column. Lower the weight of the tubing string to compress the pressure test valve of the tubing. Open the ball valve and lock it in the open position. Use one of the following procedures to lock the ball valve in the open position; 1) Sealing packer: Lower the weight of the working column and open the ball valve; Apply sufficient pressure to the annulus to cut the shear pin and activate the locking mechanism. The quantity of cuts determines the pressure of the locking mechanism. Each shear pin has a rated value of 300Psi. 2) Seat sealing packer: Lower the weight of the working column, open the ball valve, and apply sufficient pressure to the working column to cut off the shear pins. The number of shear pins determines the weight required to cut off all shear pins; Apply a small pressure (100-200Psi) to the annular space to overcome the friction of the locking mechanism O-ring.

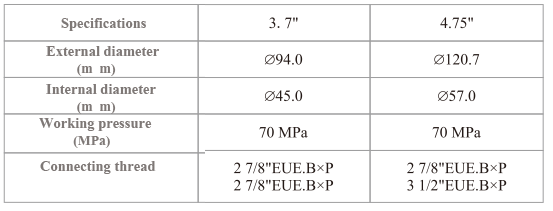

technical parameter

Address

South Section of Fenghuang 3rd Road, Gaoxin 19 Road, High tech Development Zone, Baoji City, Shaanxi Province

admin@bfdoil-tools.com

Phone

0917-6733216

13909178362

|

The company always adheres to

Guided by customer needs, we strictly control product quality, respond quickly to customer demands, efficiently provide products and solutions, and create tangible value for customers.

|

Mobile version QR code

|