Address

South Section of Fenghuang 3rd Road, Gaoxin 19 Road, High tech Development Zone, Baoji City, Shaanxi Province

Tool Introduction:

Tongjing gauge is a specialized tool used to detect the diameter size of downhole tubular objects. It is mainly used to check whether the diameter size of inner holes such as casing, tubing, and drill pipe meets the standards. It is a conventional tool for parallel operations and is mainly divided into two categories: casing Tongjing gauge and tubing and drill pipe Tongjing gauge.

Structural features:

① The locking spindle of the cutting pin keeps the tool in an open state at all times;

② After pitching, apply pressure to cut the shear pin, and the spindle descends to close the circulation hole;

③ The pawl structure can lock the downward circulation hole of the spindle after it is closed, and the circulation hole cannot be opened.

Operation:

Connect the casing to the downhole pipe string and let it pass through the wellbore smoothly. If there is any obstruction, it indicates that there is a problem with the downhole casing; When the tool for the current well is long, it can be extended by connecting another well gauge at the lower end of the well gauge; The drilling process requires constant speed and stability, with a lowering speed controlled within 10-15 columns/h. It is strictly prohibited to brake or release forcefully. When passing through the hanger, inclined point, and casing accessories, the drilling speed should be controlled at 5 columns/h; If the pipe column encounters obstruction halfway, the hanging weight should be controlled to decrease by no more than 20KN to 30KN, and the pipe column should be smoothly moved and flushed in a cyclic manner. It is strictly prohibited to suddenly stop or press hard. If the stable movement of the column and the ineffective circulation flushing, analyze the cause of the obstruction before proceeding to the next step of the operation; The speed of lowering a single piece from the bottom of the well to the 450th turn should be less than 2M/min, and continuous construction must be carried out; The time for the logging gauge to stay in the open hole section should not exceed 6 hours. The logging gauge should be thoroughly circulated and cleaned until it is clean, and the logging gauge should be removed in a timely manner.

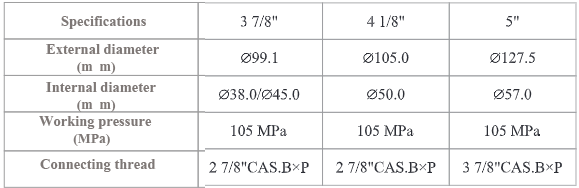

Technical parameters:

Address

South Section of Fenghuang 3rd Road, Gaoxin 19 Road, High tech Development Zone, Baoji City, Shaanxi Province

admin@bfdoil-tools.com

Phone

0917-6733216

13909178362

|

The company always adheres to

Guided by customer needs, we strictly control product quality, respond quickly to customer demands, efficiently provide products and solutions, and create tangible value for customers.

|

Mobile version QR code

|